珀金斯Perkins1204E-1206E故障排除(英文)

詳細描述

Troubleshooting

1204E-E44TA, 1204E-E44TTA and

1206E-E66TA Industrial Engines

BK1 (Engine)

MK1 (Engine)

ML1 (Engine)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

Important Safety Information

Most accidents tha t involve produc t op eration, ma intena nc e and repair are caus ed by failure to

ob serve basic safety rules or precautions . An accident can often be avoided by recog nizing pote ntially

ha za rdous situations before an accident oc curs . A person mus t be alert to pote ntial ha za rds. This

person should also ha ve the ne cessary training, skills and tools to perform the se func tions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Sa fety precautions and warning s are provided in this ma nua l and on the produc t. If the se ha za rd

warning s are not he eded, bod ily injury or death could oc cur to you or to othe r persons .

The ha za rds are identified by the “Safety Alert Symb ol” and followed by a “Signa l Word” suc h as

“DANGER”, “WARNING” or “CAUTION”. The Sa fety Alert “WARNING” label is shown below.

The me aning of this safety alert symb ol is as follows:

Attention! Become Alert! Your Safety is Involved.

The me ssage tha t appears und er the warning explains the ha za rd and can be either written or

pictorially presente d.

Op erations tha t ma y caus e produc t dama ge are identified by “NOTICE” labels on the produc t and in

this pub lication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The informa tion, specifications , and illustrations in this pub lication are on the basis of informa tion tha t

was available at the time tha t the pub lication was written. The specifications , torque s, pressure s,

me asure me nts , adjustme nts , illustrations , and othe r items can cha ng e at any time. These cha ng es can

affect the service tha t is given to the produc t. Ob tain the comp lete and mos t current informa tion before

you start any job. Pe rkins dealers or Pe rkins distributors ha ve the mos t current informa tion available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9116-01

3

Table of Contents

Table of Contents

Engine Stalls at Low RPM .................................... 94

Engine Top Speed Is Not Obtained ...................... 96

Engine Vibration Is Excessive ............................ 101

Exhaust Has Excessive Black Smoke ................ 102

Exhaust Has Excessive White Smoke ................ 104

Fuel Consumption Is Excessive .......................... 106

Fuel Contains Water ........................................... 108

Fuel Rail Pressure Problem ................................ 109

Fuel Temperature Is High .................................... 117

Inlet Air Is Restricted ............................................ 119

Inlet Air Temperature Is High .............................. 120

Intake Manifold Air Pressure Is High .................. 121

Intake Manifold Air Pressure Is Low ................... 122

Intake Manifold Air Temperature Is High ............. 123

NRS Exhaust Gas Temperature Is High ............ 124

NRS Mass Flow Rate Problem ........................... 127

Oil Consumption Is Excessive ............................ 130

Oil Contains Coolant ........................................... 132

Oil Contains Fuel ................................................ 133

Oil Pressure Is Low ............................................. 134

Power Is Intermittently Low or Power Cutout Is

Troubleshooting Section

Electronic Troubleshooting

Welding Precaution ................................................. 5

System Overview .................................................... 5

Glossary ................................................................ 12

Electronic Service Tools ........................................ 16

Indicator Lamps .................................................... 18

Replacing the ECM ............................................... 21

Self-Diagnostics .................................................... 22

Sensors and Electrical Connectors ....................... 22

Engine Wiring Information .................................... 31

ECM Harness Connector Terminals ..................... 36

Programming Parameters

Programming Parameters ..................................... 37

Test ECM Mode .................................................... 37

Factory Passwords ............................................... 37

Flash Programming .............................................. 38

Injector Code - Calibrate ....................................... 39

Mode Switch Setup ............................................... 40

Throttle Setup ....................................................... 41

Multiposition Switch Setup .................................... 44

Intermittent ........................................................ 136

Valve Lash Is Excessive ..................................... 141

Troubleshooting with a Diagnostic Code

Diagnostic Trouble Codes ................................... 142

Diagnostic Code Cross Reference ..................... 147

No Diagnostic Codes Detected ........................... 151

Customer Specified Parameters

Customer Specified Parameters ........................... 45

Customer Specified Parameters Table ................. 51

Customer Specified Parameters Worksheet ......... 54

Troubleshooting with an Event Code

Event Codes ...................................................... 152

Diagnostic Functional Tests

System Configuration Parameters

System Configuration Parameters ........................ 58

5 Volt Sensor Supply Circuit - Test ..................... 154

Analog Throttle Position Sensor Circuit - Test .... 163

CAN Data Link Circuit - Test ............................... 168

Data Link Circuit - Test ........................................ 172

Diesel Particulate Filter Identification Signal -

Symptom Troubleshooting

Acceleration Is Poor or Throttle Response Is

Poor .................................................................... 60

Alternator Is Noisy ................................................ 66

Alternator Problem ................................................ 66

Battery Problem .................................................... 66

Coolant Contains Oil ............................................. 67

Coolant Level Is Low ............................................ 67

Coolant Temperature Is High ................................ 68

Crankcase Breather Ejects Oil .............................. 71

Crankcase Fumes Disposal Tube Has Oil

Draining ............................................................... 72

Cylinder Is Noisy ................................................... 73

Diesel Particulate Filter Collects Excessive Soot .. 74

Diesel Particulate Filter Temperature Is Low ........ 75

ECM Does Not Communicate with Other

Modules .............................................................. 76

ECM Will Not Accept Factory Passwords ............. 76

Electronic Service Tool Does Not Communicate .. 77

Engine Cranks but Does Not Start ........................ 78

Engine Does Not Crank ........................................ 84

Engine Has Early Wear ........................................ 85

Engine Has Mechanical Noise (Knock) ................ 85

Engine Misfires, Runs Rough or Is Unstable ........ 86

Engine Overspeeds .............................................. 91

Engine Shutdown Occurs Intermittently ............... 92

Engine Speed Does Not Change .......................... 93

Test ................................................................... 179

Digital Throttle Position Sensor Circuit - Test ..... 183

ECM Memory - Test ............................................ 192

Electrical Connectors - Inspect ........................... 193

Engine Pressure Sensor Open or Short Circuit -

Test ................................................................... 197

Engine Speed/Timing Sensor Circuit - Test ........ 204

Engine Temperature Sensor Open or Short Circuit -

Test ................................................................... 212

Engine Temperature Sensor Open or Short Circuit -

Test ................................................................... 217

Ether Starting Aid - Test ...................................... 224

Fuel Pump Relay Circuit - Test ........................... 228

Glow Plug Starting Aid - Test .............................. 236

Idle Validation Switch Circuit - Test ..................... 242

Ignition Keyswitch Circuit and Battery Supply Circuit -

Test ................................................................... 248

Indicator Lamp Circuit - Test ............................... 255

Injector Data Incorrect - Test ............................... 258

Injector Solenoid Circuit - Test ............................ 260

Mode Selection Circuit - Test .............................. 267

Motorized Valve - Test ........................................ 271

PTO Switch Circuit - Test .................................... 276

Sensor Calibration Required - Test ..................... 279

Solenoid Valve - Test .......................................... 282

This document is printed from SPI². Not for RESALE

![]()

4

KENR9116-01

Table of Contents

Soot Sensor - Test .............................................. 288

Throttle Switch Circuit - Test ............................... 291

Valve Position Sensor - Test ............................... 295

Water In Fuel Sensor - Test ................................ 301

Index Section

Index ................................................................... 306

This document is printed from SPI². Not for RESALE

![]()

KENR9116-01

5

Troubleshooting Section

Troubleshooting Section

Electronic Troubleshooting

i04029202

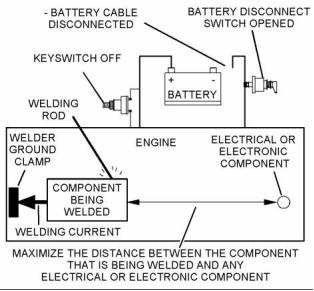

Welding Precaution

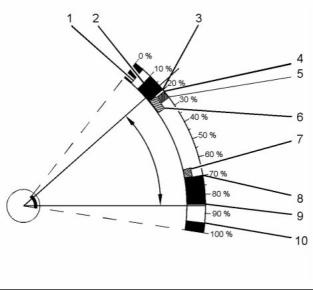

Correct welding procedures are necessary in order to

avoid damage to the following components:

• Electronic Control Module (ECM) on the engine

• Clean Emissions Module (CEM)

• Sensors

g01143634

Illustration 1

• Associated components

Service welding guide (typical diagram)

Components for the driven equipment should also be

considered. When possible, remove the component

that requires welding. When welding on an engine

that is equipped with an ECM and removal of the

component is not possible, the following procedure

must be followed. This procedure minimizes the risk

to the electronic components.

5. When possible, connect the ground clamp for

the welding equipment directly to the engine

component that will be welded. Place the clamp

as close as possible to the weld. Close positioning

reduces the risk of welding current damage to the

engine bearings, to the electrical components,

and to other components.

1. Stop the engine. Remove the electrical power

from the ECM.

6. Protect the wiring harnesses from welding debris

and/or from welding spatter.

2. Ensure that the fuel supply to the engine is turned

off.

7. Use standard welding procedures to weld the

materials together.

3. Disconnect the negative battery cable from the

battery. If a battery disconnect switch is installed,

open the switch.

i04155807

System Overview

4. Disconnect all electronic components from

the wiring harnesses. Include the following

components:

The engine has an electronic control system. The

system also monitors the Diesel Particulate Filter

(DPF) and the NOx Reduction System (NRS).

• Electronic components for the driven equipment

• ECM

The control system consists of the following

components:

• Sensors

• Electronically controlled valves

• Relays

• Electronic Control Module (ECM)

• Software (flash file)

• Wiring

• Aftertreatment ID module

NOTICE

• Sensors

Do not use electrical components (ECM or ECM sen-

sors) or electronic component grounding points for

grounding the welder.

• Actuators

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

6

KENR9116-01

Troubleshooting Section

The following information provides a general

description of the control system. Refer to Systems

Operation, Testing, and Adjusting for detailed

information about the control system.

Electronic Control Circuit Diagram

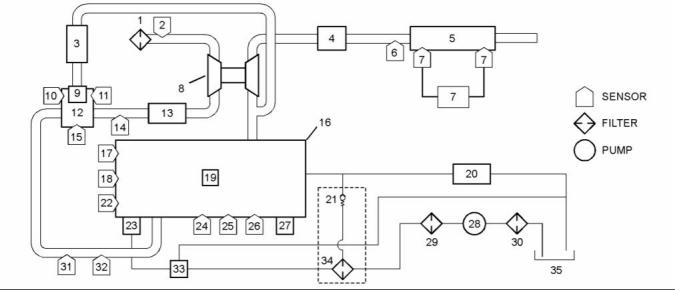

g02476570

Illustration 2

Electronic control circuit diagram for the 1204E-E44 engine

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9116-01

7

Troubleshooting Section

g02476572

Illustration 3

Electronic control circuit diagram for the 1206E-E66 engine

Block Diagram

Refer to Illustration 4 and Illustration 5 for block

diagrams of the control system.

This document is printed from SPI². Not for RESALE

![]()

![]()

8

KENR9116-01

Troubleshooting Section

g02477761

Illustration 4

Block diagram for the 1204E and 1206E engines with a single turbocharger

(1) Air cleaner

(13) Air-to-air aftercooler

(25) Oil pressure sensor

(2) Air inlet temperature sensor

(3) NRS cooler

(14) Wastegate regulator

(15) NRS outlet pressure sensor

(16) Engine

(17) Coolant temperature sensor

(18) Primary speed/timing sensor

(19) Fuel injectors

(26) Barometric pressure sensor

(27) ECM

(28) Electric fuel lift pump

(29) Primary fuel filter

(4) Exhaust back pressure valve

(5) Diesel Oxidation Catalyst (DOC) and

Diesel Particulate Filter (DPF)

(6) DPF inlet temperature sensor

(7) Soot sensor

(8) Turbocharger

(9) NRS valve

(10) NRS temperature sensor

(11) NRS inlet pressure sensor

(12) NRS mixer

(30) In-line fuel strainer

(31) Intake manifold pressure sensor

(32) Intake manifold air temperature sensor

(33) Transfer pump inlet regulator

(34) Secondary fuel filter

(35) Fuel tank

(20) Return fuel cooler

(21) Return fuel pressure relief valve

(22) Secondary speed/timing sensor

(23) High-pressure fuel pump/transfer

pump/fuel temperature sensor

(24) Fuel rail pressure sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9116-01

9

Troubleshooting Section

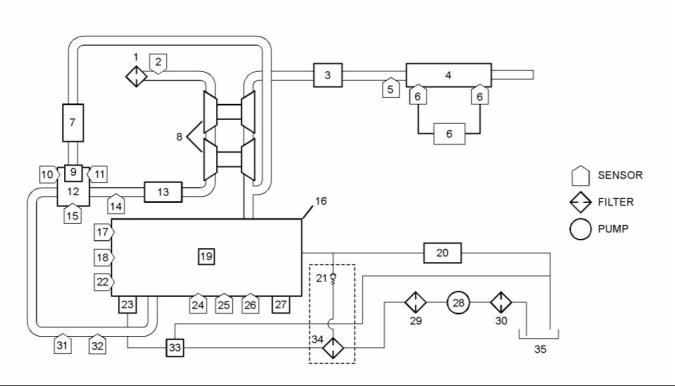

g02477778

Illustration 5

Block diagram for the 1204E-E44TTA engine with twin turbochargers

(1) Air cleaner

(13) Air-to-air aftercooler

(25) Oil pressure sensor

(2) Air inlet temperature sensor

(3) Exhaust back pressure valve

(4) Diesel Oxidation Catalyst (DOC) and

Diesel Particulate Filter (DPF)

(5) DPF inlet temperature sensor

(6) Soot sensor

(7) NRS cooler

(8) Turbochargers

(9) NRS valve

(14) Wastegate regulator

(15) NRS outlet pressure sensor

(16) Engine

(17) Coolant temperature sensor

(18) Primary speed/timing sensor

(19) Fuel injectors

(26) Barometric pressure sensor

(27) ECM

(28) Electric fuel lift pump

(29) Primary fuel filter

(30) In-line fuel strainer

(31) Intake manifold pressure sensor

(32) Intake manifold air temperature sensor

(33) Transfer pump inlet regulator

(34) Secondary fuel filter

(35) Fuel tank

(20) Return fuel cooler

(21) Return fuel pressure relief valve

(22) Secondary speed/timing sensor

(23) High-pressure fuel pump/transfer

pump/fuel temperature sensor

(24) Fuel rail pressure sensor

(10) NRS temperature sensor

(11) NRS inlet pressure sensor

(12) NRS mixer

System Operation

Engine Governor

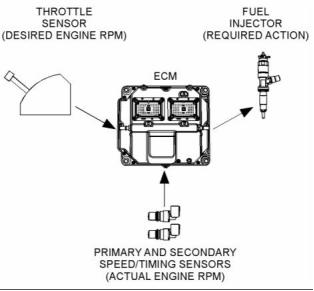

The ECM governs the engine. The ECM determines

the timing, the injection pressure, and the amount

of fuel that is delivered to each cylinder. These

factors are based on the actual conditions and on the

desired conditions at any given time during starting

and operation.

The governor uses the throttle position sensor to

determine the desired engine speed. The governor

compares the desired engine speed to the actual

engine speed. The actual engine speed is determined

through interpretation of the signals that are received

by the ECM from the engine speed/timing sensors. If

the desired engine speed is greater than the actual

engine speed, the governor injects more fuel in order

to increase engine speed.

This document is printed from SPI². Not for RESALE

![]()

![]()

10

KENR9116-01

Troubleshooting Section

Fuel Injection

The ECM sends a high voltage signal to the injector

solenoids in order to energize the solenoids. By

controlling the timing and the duration of the high

voltage signal, the ECM can control the following

aspects of injection:

• Injection timing

• Fuel delivery

The flash file inside the ECM establishes certain

limits on the amount of fuel that can be injected.

The FRC Fuel Limit is a limit that is based on the

intake manifold pressure. The FRC Fuel Limit is used

to control the air/fuel ratio for control of emissions.

When the ECM senses a higher intake manifold

pressure, the ECM increases the FRC Fuel Limit. A

higher intake manifold pressure indicates that there

is more air in the cylinder. When the ECM increases

the FRC Fuel Limit, the ECM allows more fuel into

the cylinder.

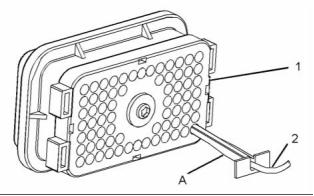

g01860934

Illustration 6

Typical example

The Rated Fuel Limit is a limit that is based on the

power rating of the engine and on the engine rpm.

The Rated Fuel Limit is like the rack stops and the

torque spring on a mechanically governed engine.

The Rated Fuel Limit provides the power curves

and the torque curves for a specific engine family

and a specific engine rating. All of these limits are

determined at the factory. These limits cannot be

changed.

The desired engine speed is typically determined by

one of the following conditions:

• The position of the throttle

• The desired engine speed in Power Take-Off (PTO)

Timing Considerations

Once the governor has determined the amount of

fuel that is required, the governor must determine

the timing of the fuel injection. Fuel injection timing is

determined by the ECM after considering input from

the following components:

Customer Parameters and Engine Speed

Governing

A unique feature with electronic engines is customer

specified parameters. These parameters allow the

owner of the machine to fine-tune the ECM for engine

operation. Fine-tuning the ECM allows the machine

owner to accommodate the typical usage of the

machine and the power train of the machine.

• Coolant temperature sensor

• Intake manifold air temperature sensor

• Intake manifold pressure sensor

• Barometric pressure sensor

Many of the customer parameters provide additional

restrictions on the actions that will be performed by

the ECM in response to input from the operator. The

PTO Top Engine Limit is an engine rpm limit that is

used by the ECM to limit the fuel during operation of

the PTO. The ECM will not fuel the injectors above

this rpm.

The ECM adjusts timing for optimum engine

performance and fuel economy. Actual timing and

desired timing cannot be viewed with the electronic

service tool. The ECM determines the location of

top center of the number one cylinder from the

signals that are provided by the engine speed/timing

sensors. The ECM determines when injection should

occur relative to top center position. The ECM then

provides the signal to the injector at the desired time.

Some parameters are intended to notify the operator

of potential engine damage (engine monitoring

parameters). Some parameters enhance fuel

economy (machine speed, engine speed limit,

and idle shutdown). Other parameters are used to

enhance the engine installation into the machine.

Other parameters are used to provide operating

information to the owner of the machine.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9116-01

11

Troubleshooting Section

Other ECM Functions for

Performance

“Lifetime Total Engine Revolutions” is the total

number of revolutions that have been completed by

the engine crankshaft.

The ECM can also provide enhanced control of the

engine for machine functions such as controlling the

cooling fan. Refer to Troubleshooting, “Configuration

Parameters” for supplemental information about the

systems that can be monitored by the ECM in order

to provide enhanced machine performance, fuel

economy, and convenience for the operator.

“Average Load Factor” provides relative engine

operating information. “Average Load Factor”

compares actual operating information of the engine

to the maximum engine operation that is available.

“Average Load Factor” is determined by using “Total

Max Fuel”, “Total Idle Fuel”, and “Total Fuel”. All of

these parameters are available with the electronic

service tool. These parameters are available within

the menu for “Current Totals”.

ECM Lifetime Totals

The ECM maintains total data of the engine for the

following parameters:

Programmable Parameters

Certain parameters that affect engine operation

may be changed with the electronic service tool.

The parameters are stored in the ECM, and the

parameters are protected from unauthorized changes

by passwords. These parameters are either system

configuration parameters or customer parameters.

• “Total Operating Hours”

• “Engine Lifetime Hours”

• “Total Idle Time”

• “Total Idle Fuel”

System configuration parameters are set at the

factory. System configuration parameters affect

emissions or power ratings within an engine family.

Factory passwords must be obtained and factory

passwords must be used to change the system

configuration parameters.

• “Total Fuel”

• “Total Max Fuel”

• “Engine Starts”

Customer parameters are variable. Customer

parameters affect the following characteristics within

the limits that are set by the factory, by the monitoring

system, and by PTO operation:

• “Lifetime Total Engine Revolutions”

• “Average Load Factor”

The “Total Operating Hours” is the operating hours of

the engine. The operating hours do not include the

time when the ECM is powered but the engine is not

running.

• Rpm ratings

• Power ratings

Customer passwords may be required to change

customer specified parameters.

The “Engine Lifetime Hours” is the number of hours

when electrical power has been applied to the

engine. These hours will include the time when the

ECM is powered but the engine is not running.

Some of the parameters may affect engine operation

in an unusual way. An operator might not expect

this type of effect. Without adequate training,

these parameters may lead to power complaints

or performance complaints even though the

performance of the engine is to the specification.

“Total Idle Time” and “Total Idle Fuel” can include

operating time when the engine is not operating

under a load.

Fuel Information can be displayed in US gallons or

in liters.

Refer to Troubleshooting, “Configuration Parameters”

for additional information on this subject.

“Total Fuel” is the total amount of fuel that is

consumed by the engine during operation.

Passwords

“Total Max Fuel” is the maximum amount of fuel that

could have been consumed by the engine during

operation.

System configuration parameters are protected by

factory passwords. Factory passwords are calculated

on a computer system that is available only to

Perkins Distributors. Since factory passwords contain

alphabetic characters, only the electronic service

tool may change system configuration parameters.

System configuration parameters affect the power

rating family or emissions.

“Engine Starts” is the total number of times when the

engine has been started.

This document is printed from SPI². Not for RESALE

![]()

12

KENR9116-01

Troubleshooting Section

Customer parameters can be protected by

customer passwords. The customer passwords are

programmed by the customer. Factory passwords

can be used to change customer passwords if

customer passwords are lost.

Communication Adapter Tool – The

communication adapter provides a communication

link between the ECM and the electronic service tool.

Coolant Temperature Sensor – The coolant

temperature sensor detects the engine coolant

temperature for all normal operating conditions and

for engine monitoring.

Refer to Troubleshooting, “Factory Passwords” for

additional information on this subject.

Data Link – The data link is a serial communication

port that is used for communication with other devices

such as the electronic service tool.

i04156374

Glossary

Derate – Certain engine conditions will generate

event codes. Also, engine may be derated. The map

for the engine derate is programmed into the ECM

software. The type of derate can be one or more of

three types: reduction of rated power, reduction of

rated engine speed, and reduction of rated machine

speed for OEM products.

Active Diagnostic Code – An active diagnostic

code alerts the operator or the service technician that

an electronic system malfunction is currently present.

Refer to the term “Diagnostic Code” in this glossary.

Aftertreatment – Aftertreatment is a system that is

used to remove pollutants from exhaust gases. The

system consists of a Diesel Oxidation Catalyst (DOC)

and a Catalyzed Diesel Particulate Filter (CDPF).

Desired Engine Speed – The desired engine speed

is input to the electronic governor within the ECM.

The electronic governor uses the signal from the

throttle position sensor, the engine speed/timing

sensor, and other sensors in order to determine the

desired engine speed.

Alternating Current (AC) – Alternating current is an

electric current that reverses direction at a regular

interval that is reoccurring.

Diagnostic Trouble Code – A diagnostic trouble

code is sometimes referred to as a fault code. These

codes indicate an electronic system malfunction.

Before Top Center (BTC) – BTC is the 180 degrees

of crankshaft rotation before the piston reaches the

top center position in the normal direction of rotation.

Diagnostic Lamp – The diagnostic lamp is also

called the warning lamp. The diagnostic lamp is used

to warn the operator of the presence of an active

diagnostic code. The lamp may not be included in

all applications.

Breakout Harness – A breakout harness is a

test harness that is designed to connect into the

engine harness. This connection allows a normal

circuit operation and the connection simultaneously

provides a Breakout T in order to measure the

signals.

Diesel Oxidation Catalyst – The Diesel Oxidation

Catalyst is also known as the (DOC). The DOC is a

device in the exhaust system that oxidizes certain

elements in the exhaust gases. These elements can

include carbon monoxide (CO), hydrocarbons and

the soluble organic fractions (SOF) of particulate

matter.

Bypass Circuit – A bypass circuit is a circuit that is

used as a substitute circuit for an existing circuit. A

bypass circuit is typically used as a test circuit.

CAN Data Link (see also J1939 CAN Data Link) –

The CAN Data Link is a serial communications

port that is used for communication with other

microprocessor-based devices.

Digital Sensor Return – The common line (ground)

from the ECM is used as ground for the digital

sensors.

Catalyzed Diesel Particulate Filter – The Catalyzed

Diesel Particulate Filter (CDPF) filters particulates

from the exhaust gases. A coating on the internal

surfaces reacts with the hot exhaust gases in order

to burn off the particulates. This process prevents the

CDPF from becoming blocked with soot.

Digital Sensors – Digital sensors produce a pulse

width modulated signal. Digital sensors are supplied

with power from the ECM.

Digital Sensor Supply – The power supply for the

digital sensors is provided by the ECM.

Clean Emissions Module – The Clean Emissions

Module (CEM) includes all the components of the

aftertreatment system.

Direct Current (DC) – Direct current is the type of

current that flows consistently in only one direction.

DT, DT Connector, or Deutsch DT – This design is

a type of connector that is used on this engine. The

connectors are manufactured by Deutsch.

Code – Refer to “Diagnostic Trouble Code”.

This document is printed from SPI². Not for RESALE

![]()

KENR9116-01

13

Troubleshooting Section

Duty Cycle – Refer to “Pulse Width Modulation”.

Failure Mode Identifier (FMI) – This identifier

indicates the type of failure that is associated with

the component. The FMI has been adopted from the

SAE practice of J1587 diagnostics. The FMI follows

the parameter identifier (PID) in the descriptions of

the fault code. The descriptions of the FMIs are in

the following list.

Electronic Engine Control – The electronic

engine control is a complete electronic system.

The electronic engine control monitors the engine

operation under all conditions. The electronic engine

control also controls the engine operation under all

conditions.

0 – The data is valid but the data is above the normal

Electronic Control Module (ECM) – The ECM

is the control computer of the engine. The ECM

provides power to the electronics. The ECM monitors

data that is input from the sensors of the engine. The

ECM acts as a governor in order to control the speed

and the power of the engine.

operational range.

1 – The data is valid but the data is below the normal

operational range.

2 – The data is erratic, intermittent, or incorrect.

Electronic Service Tool – The electronic service

tool allows a computer (PC) to communicate with the

ECM.

3 – The voltage is above normal or the voltage is

shorted high.

4 – The voltage is below normal or the voltage is

shorted low.

Engine Monitoring – Engine Monitoring is the part

of the electronic engine control that monitors the

sensors. Engine monitoring also warns the operator

of detected problems.

5 – The current is below normal or the circuit is open.

6 – The current is above normal or the circuit is

grounded.

Engine Oil Pressure Sensor – The engine oil

pressure sensor measures engine oil pressure. The

sensor sends a signal to the ECM that is dependent

on the engine oil pressure.

7 – The mechanical system is not responding

properly.

Engine Speed/Timing Sensor – An engine

speed/timing sensor is a hall effect switch that

provides a digital signal to the ECM. The ECM

interprets this signal as the crankshaft position and

the engine speed. Two sensors are used to provide

the speed and timing signals to the ECM. The primary

sensor is associated with the crankshaft and the

secondary sensor is associated with the camshaft.

8 – There is an abnormal frequency, an abnormal

pulse width, or an abnormal time period.

9 – There has been an abnormal update.

10 – There is an abnormal rate of change.

11 – The failure mode is not identifiable.

12 – The device or the component is damaged.

13 – The device requires calibration.

Ether Injection – Ether injection is a starting aid in

cold conditions. Glow plugs are used as a starting

aid when the ambient temperature is between 5° C

(41° F) and −25° C (−13° F). At a temperature that

is lower than −25° C (−13° F), the glow plugs are

disabled and ether injection is used.

14 – There is a special instruction for the device.

15 – The signal from the device is high (least severe).

Event Code – An event code may be activated

in order to indicate an abnormal engine operating

condition. These codes usually indicate a mechanical

problem instead of an electrical system problem.

16 – The signal from the device is high (moderate

severity).

17 – The signal from the device is low (least severe).

Exhaust Back Pressure Valve – The exhaust back

pressure valve regulates the gas pressure in the

exhaust system. The valve can restrict the flow of

exhaust gases in order to increase the exhaust back

pressure. An increase in exhaust back pressure will

increase the temperature of the exhaust gases. The

increase in temperature will improve the process that

burns off the soot in the CDPF.

18 – The signal from the device is low (moderate

severity).

19 – There is an error in the data from the device.

31 – The device has failed and the engine has shut

down.

This document is printed from SPI². Not for RESALE

![]()

14

KENR9116-01

Troubleshooting Section

Flash File – This file is software that is inside

the ECM. The file contains all the instructions

(software) for the ECM and the file contains the

performance maps for a specific engine. The file may

be reprogrammed through flash programming.

Harness – The harness is the bundle of wiring

(loom) that connects all components of the electronic

system.

Hertz (Hz) – Hertz is the measure of electrical

frequency in cycles per second.

Flash Programming – Flash programming is the

method of programming or updating an ECM with

an electronic service tool over the data link instead

of replacing components.

High Pressure Fuel Pump – This pump is a device

that supplies fuel under pressure to the fuel rail

(high-pressure fuel rail).

FRC – See “Fuel Ratio Control”.

High Pressure Fuel Rail – See “Fuel Rail”.

Fuel Pump – See “High Pressure Fuel Pump”.

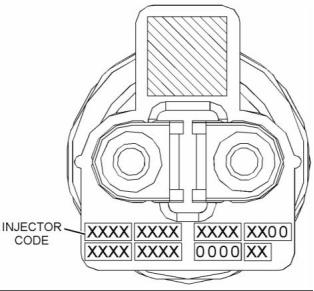

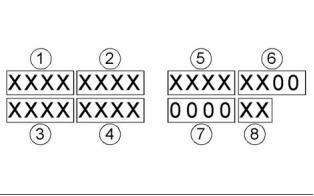

Injector Trim Codes – Injector trim codes are codes

that contain 30 characters. The codes are supplied

with new injectors. The code is input through the

electronic service tool into the ECM. The injector trim

codes compensate for variances in manufacturing

of the electronic unit injector and for the life of the

electronic unit injector.

Fuel Rail – This item is sometimes referred to as the

High Pressure Fuel Rail. The fuel rail supplies fuel to

the electronic unit injectors. The high-pressure fuel

pump and the fuel rail pressure sensor work with the

ECM in order to maintain the desired fuel pressure

in the fuel rail. This pressure is determined by

calibration of the engine in order to enable the engine

to meet emissions and performance requirements.

Intake Manifold Air Temperature Sensor – The

intake manifold air temperature sensor detects the

air temperature in the intake manifold. The ECM

monitors the air temperature and other data in the

intake manifold in order to adjust injection timing and

other performance functions.

Fuel Rail Pressure Sensor – The fuel rail pressure

sensor sends a signal to the ECM that is dependent

on the pressure of the fuel in the fuel rail.

Fuel Ratio Control (FRC) – The FRC is a limit that

is based on the control of the ratio of the fuel to air.

The FRC is used for purposes of emission control.

When the ECM senses a higher intake manifold

air pressure (more air into the cylinder), the FRC

increases the FRC Limit (more fuel into the cylinder).

Intake Manifold Pressure Sensor – The Intake

Manifold Pressure Sensor measures the pressure

in the intake manifold. The pressure in the intake

manifold may be different to the pressure outside

the engine (atmospheric pressure). The difference

in pressure may be caused by an increase in air

pressure by a turbocharger.

Full Load Setting (FLS) – The FLS is the parameter

that represents the fuel system adjustment. This

adjustment is made at the factory in order to

fine-tune the fuel system. This parameter must be

programmed.

Integrated Electronic Controls – The engine is

designed with the electronic controls as a necessary

part of the system. The engine will not operate

without the electronic controls.

Full Torque Setting (FTS) – The FTS is the

parameter that represents the adjustment for the

engine torque. This adjustment is made at the factory

in order to fine-tune the fuel system. This adjustment

is made with the FLS. This parameter must be

programmed.

J1939 CAN Data Link – This data link is a SAE

standard diagnostic communications data link that is

used to communicate between the ECM and other

electronic devices.

Logged Diagnostic Codes – Logged diagnostic

codes are codes which are stored in the memory.

These codes are an indicator of possible causes for

intermittent problems. Refer to the term “Diagnostic

Trouble Codes” for more information.

Glow Plug – The glow plug is an optional starting aid

for cold conditions. One glow plug is installed in each

combustion chamber in order to improve the ability of

the engine to start. The ECM uses information from

the engine sensors to determine when the glow plug

relay must provide power to each glow plug. Each

of the glow plugs then provides a hot surface in the

combustion chamber in order to vaporize the mixture

of air and fuel. The vaporization improves ignition

during the compression stroke of the cylinder.

NOx Reduction System – The NOx Reduction

System recycles a portion of the exhaust gases back

into the inlet air. The recirculation reduces the oxides

of nitrogen (NOx) in the exhaust gases. The recycled

exhaust gas passes through a cooler before being

introduced into the inlet air.

Glow Plug Relay – The glow plug relay is controlled

by the ECM in order to provide high current to the

glow plugs.

OEM – OEM is an abbreviation for the Original

Equipment Manufacturer. The OEM is the

manufacturer of the machine or the vehicle that uses

the engine.

This document is printed from SPI². Not for RESALE

![]()

KENR9116-01

15

Troubleshooting Section

Open Circuit – An open circuit is a condition that is

caused by an open switch, or by an electrical wire

or a connection that is broken. When this condition

exists, the signal o, r the supply voltage can no longer

reach the intended destination.

Parameter – A parameter is a value or a limit that is

programmable. A parameter helps determine specific

characteristics or behaviors of the engine.

Password – A password is a group of numeric

characters or a group of alphanumeric characters

that is designed to restrict access to parameters. The

electronic system requires correct passwords in order

to change some parameters (Factory Passwords).

Refer to Troubleshooting, “Factory Passwords” for

more information.

Personality Module – See “Flash File”.

Power Cycling – Power cycling refers to the action

of cycling the keyswitch from any position to the OFF

position, and to the START/RUN position.

g01858875

Illustration 7

Rated Fuel Limit – The rated fuel limit is a limit that

is based on the power rating of the engine and on the

engine rpm. The Rated Fuel Limit enables the engine

power and torque outputs to conform to the power

and torque curves of a specific engine model. These

limits are in the flash file and these limits cannot be

changed.

Pressure Limiting Valve (PLV) – The PLV is a valve

in the fuel rail that prevents excessive pressure. The

PLV will reduce the pressure to a safe level that will

limit engine operation but the reduced pressure will

not stop the engine.

Primary Speed/Timing Sensor – This sensor

determines the position of the crankshaft during

engine operation. If the primary speed/timing

sensor fails during engine operation, the secondary

speed/timing sensor is used to provide the signal.

Reference Voltage – Reference voltage is a

regulated voltage and a steady voltage that is

supplied by the ECM to a sensor. The reference

voltage is used by the sensor to generate a signal

voltage.

Pulse Width Modulation (PWM) – The PWM is a

signal that consists of pulses that are of variable

width. These pulses occur at fixed intervals. The ratio

of “TIME ON” versus “TIME OFF” can be varied. This

ratio is also referred to as a duty cycle.

Relay – A relay is an electromechanical switch. A

flow of electricity in one circuit is used to control the

flow of electricity in another circuit. A small current or

voltage is applied to a relay in order to switch a much

larger current or voltage.

Secondary Speed/Timing Sensor – This sensor

determines the position of the camshaft during engine

operation. If the primary speed/timing sensor fails

during engine operation, the secondary speed/timing

sensor is used to provide the signal.

Sensor – A sensor is a device that is used to

detect the current value of pressure or temperature,

or mechanical movement. The information that is

detected is converted into an electrical signal.

Short Circuit – A short circuit is a condition that has

an electrical circuit that is inadvertently connected to

an undesirable point. An example of a short circuit

is a wire which rubs against a vehicle frame and

this rubbing eventually wears off the wire insulation.

Electrical contact with the frame is made and results

in a short circuit.

This document is printed from SPI². Not for RESALE

![]()

![]()

16

KENR9116-01

Troubleshooting Section

Signal – The signal is a voltage or a waveform that

is used in order to transmit information typically from

a sensor to the ECM.

Wastegate – The wastegate is a device in a

turbocharged engine that controls the maximum

boost pressure that is provided to the inlet manifold.

Suction Control Valve (SCV) – The SCV is a control

device in the high-pressure fuel pump. The valve

controls the pressure in the fuel rail by varying the

amount of fuel that enters the chambers in the pump.

Wastegate Regulator – The wastegate regulator

controls the pressure in the intake manifold to a

value that is determined by the ECM. The wastegate

regulator provides the interface between the ECM

and the mechanical system. The wastegate regulates

intake manifold pressure to the desired value that is

determined by the software.

Supply Voltage – The supply voltage is a continuous

voltage that is supplied to a component. The power

may be generated by the ECM or the power may be

battery voltage that is supplied by the engine wiring.

i04084033

Suspect Parameter Number (SPN) – The SPN is a

J1939 number that identifies the specific component

of the electronic control system that has experienced

a diagnostic code.

Electronic Service Tools

Perkins electronic service tools are designed to help

the service technician:

System Configuration Parameters – System

configuration parameters are parameters that affect

emissions and/or operating characteristics of the

engine.

• Retrieve diagnostic codes.

• Diagnose electrical problems.

• Read parameters.

Tattletale – Certain parameters that affect the

operation of the engine are stored in the ECM.

These parameters can be changed by use of the

electronic service tool. The tattletale logs the number

of changes that have been made to the parameter.

The tattletale is stored in the ECM.

• Program parameters.

• Install injector trim codes.

Throttle Position – The throttle position is the

interpretation by the ECM of the signal from the

throttle position sensor or the throttle switch.

Required Service Tools

Table 1

Throttle Position Sensor – The throttle position

sensor is a sensor that is normally connected to an

accelerator pedal or a hand lever. This sensor sends

a signal to the ECM that is used to calculate desired

engine speed.

Required Service Tools

Part Number

CH11155

Description

Crimp Tool (12−AWG TO 18−AWG)

Wire Removal Tool

2900A019

Throttle Switch – The throttle switch sends a signal

to the ECM that is used to calculate desired engine

speed.

27610285

Removal Tool

-

Suitable Digital Multimeter

Top Center Position – The top center position refers

to the crankshaft position when the engine piston

position is at the highest point of travel. The engine

must be turned in the normal direction of rotation in

order to reach this point.

Two short jumper wires are needed to check the

continuity of some wiring harness circuits by shorting

two adjacent terminals together in a connector. A

long extension wire may also be needed to check the

continuity of some wiring harness circuits.

Total Tattletale – The total tattletale is the total

number of changes to all the parameters that are

stored in the ECM.

Optional Service Tools

Table 2 lists the optional service tools that can be

used when the engine is serviced.

Wait To Start Lamp – This lamp is included in the

cold starting aid circuit in order to indicate when the

wait to start period is active. The lamp will go off

when the engine is ready to be started. The glow

plugs may not have deactivated.

This document is printed from SPI². Not for RESALE

![]()

KENR9116-01

17

Troubleshooting Section

Table 2

Table 3

Part Number

U5MK1092

Description

Service Tools for the Use of the Electronic

Service Tool

Spoon Probe Kit(MULTIMETER)

Part

Description

-

or

-

Suitable Digital Pressure Indicator

or

Engine Pressure Group

Number

-(1)

Single Use Program License

-

-

-

(1)

Suitable Battery Load Tester

Data Subscription for All Engines

Suitable Temperature Adapter

(MULTIMETER)

Communication Adapter (Electronic

Service Tool to the ECM interface)

27610251

27610164

28170107

2900A038

Bypass Harness As

Harness as

Adapter Cable As

(1) Refer to Perkins Engine Company Limited.

Note: For more information on the Electronic

Service Tool and the PC requirements, refer to the

documentation that accompanies the software for the

Electronic Service Tool.

Perkins Electronic Service Tool

The Perkins Electronic Service Tool can display the

following information:

Connecting the Electronic Service Tool

and the Communication Adapter II

• Status of all pressure sensors and temperature

sensors

• Programmable parameter settings

• Active diagnostic codes and logged diagnostic

codes

• Logged events

• Histograms

The Electronic Service Tool can also be used to

perform the following functions:

• Diagnostic tests

• Sensor calibrations

• Programming of flash files and injector trim codes

• Parameter programming

• Copy configuration function for ECM replacement

• Data logging

• Graphs (real time)

Table 3 lists the service tools that are required in

order to use the Electronic Service Tool.

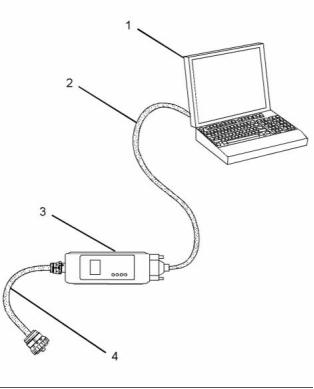

g01121866

Illustration 8

(1) Personal Computer (PC)

(2) Adapter Cable (Computer Serial Port)

(3) Communication Adapter II

(4) Adapter Cable Assembly

Note: Items (2), (3) and (4) are part of the

Communication Adapter II kit.

Use the following procedure in order to connect

the Electronic Service Tool and the Communication

Adapter II.

This document is printed from SPI². Not for RESALE

![]()

![]()

18

KENR9116-01

Troubleshooting Section

1. Turn the keyswitch to the OFF position.

Warning Lamp

2. Connect cable (2) between the “COMPUTER”

end of communication adapter (3) and the RS232

serial port of PC (1).

Lamp check – When the keyswitch is turned to ON,

the lamp will come on for 2 seconds. The lamp will

then go off unless there is an active warning.

Note: The Adapter Cable Assembly (4) is required to

connect to the USB port on computers that are not

equipped with an RS232 serial port.

Flashing – The lamp will be flashing when a

“warning” or a “warning and derate” is active. This

includes low oil pressure.

3. Connect cable (4) between the “DATA LINK” end

of communication adapter (3) and the service tool

connector.

On – The lamp will be on when the shutdown level

has been reached. The “Shutdown” lamp will also

be on.

4. Place the keyswitch in the ON position. If the

Electronic Service Tool and the communication

adapter do not communicate with the Electronic

Control Module (ECM), refer to the diagnostic

procedure Troubleshooting, “Electronic Service

Tool DoesNot Communicate”.

Wait to Start Lamp

Lamp check – When the keyswitch is turned to ON,

the lamp will come on for 2 seconds. The lamp will

then go off unless “Wait to Start” is active.

On – The lamp is on during a “Wait to Start” period.

i03834091

Low Oil Pressure

Indicator Lamps

Lamp check – When the keyswitch is turned to ON,

the lamp will come on for 2 seconds. The lamp will

then go off unless there is an active warning.

Indicator Lamps

On – The lamp will come on when a low oil pressure

event is detected. The “Warning” lamp and the

“Shutdown” lamp may also come on.

Four lamps are available as options. The “Shutdown”

lamp and the “Warning” lamp will normally be installed

in the application. Dedicated optional lamps for other

items may also be installed. The remaining optional

lamps are “Wait to start” and “Low oil pressure”.

Note: On a cold start, when the Electronic Control

Module (ECM) determines that it is necessary for the

glow plugs to be activated prior to starting, a lamp

output will indicate that the operator needs to “Wait

to Start”. It is possible that starting aids may be used

during the cranking of the engine. Starting aids may

be used if the engine has previously been started.

The “Wait to Start” lamp will not be active in these

conditions.

The “Shutdown” lamp and the “Warning” lamp can

also be used to indicate a diagnostic code by use of

the “Flash Code” feature. The “Flash Code” feature

can be used to indicate all active diagnostic codes

and logged diagnostic codes.

Functions of the Lamps

Color of Lamps

Shutdown Lamp

Typically, the “Shutdown” lamp is colored red and the

“Warning” lamp is colored amber. The other lamps

are optional.

Lamp check – When the keyswitch is turned to ON,

the lamp will come on for 2 seconds. The lamp will

then go off unless there is an active warning.

Flashing – The lamp will be flashing when a derate

is active or when a derate is present because of

an active diagnostic code. An example of an active

diagnostic code is “System Voltage High”.

On – The lamp will be on when the shutdown level

in the engine protection strategy has been reached.

The “Warning” lamp will also be on.

This document is printed from SPI². Not for RESALE

![]()

KENR9116-01

19

Troubleshooting Section

Operation of the Indicator Lamps

Table 4

Warning

Lamp

(Alert

Shutdown

Lamp

(Action

Lamp State

Lamp Check

No Faults

Description of the Indication

Engine State

Lamp)

Lamp)

On

On

When the keyswitch is moved to the

ON position, the lamps come on for

a period of 2 seconds and the lamps

will then go off.

The keyswitch is in the ON position but

the engine has not yet been cranked.

Off

On

Off

Off

With the engine in operation, there

are no active warnings, diagnostic

codes or event codes.

The engine is operating with no detected

faults.

Active

Diagnostic

If the warning lamp comes on during

engine operation, this indicates

that an active diagnostic code (an

electrical fault) is present.

The engine is operating normally but

there is one or more faults with the

electronic management system for the

engine.

On

Flashing

Derate

(A derate is

caused by

certain active

codes.)

If the warning lamp comes on and the The engine is operating but there is one

shutdown lamp flashes during engine or more active diagnostic codes that

operation, this indicates that an active have initiated an engine derate.

diagnostic code (an electrical fault) is

present. The diagnostic is sufficiently

serious in order to cause an engine

derate.

Flashing

Off

Warning

(Warning only) during operation of the engine,

the lamp indicates that one or

When the warning lamp flashes

The engine is operating normally.

However, there is one or more of the

monitored engine parameters that are

outside of the range that is acceptable.

more of the warning values for the

engine protection strategy has been

exceeded. However, the value has

not been exceeded to a level that will

cause a derate or a shutdown.

Flashing

Flashing

Off

Warning

(Warning only) Diesel Particulate Filter (DPF).

There is a high soot loading in the

The soot loading in the DPF has

reached 100%. The engine will be

derated. The lamp warns the operator

that the engine needs to be operated in

a mode that promotes regeneration.

Flashing

Derate

(Warning and

Derate)

If both the warning lamp and

shutdown lamp flash during operation one or more of the monitored engine

of the engine, the lamps indicate that parameters is outside of the acceptable

The engine is operating. However,

one or more of the values for the

range. The acceptable range has been

engine protection strategy have been exceeded to a level which requires a

exceeded beyond the level that will

cause an engine derate.

warning and an engine derate.

Flashing

On

On

On

Very high DPF The soot loading in the DPF is high.

soot loading

The soot loading in the DPF has reached

120%. The engine must be operated in

a mode that promotes regeneration.

Engine

Shutdown

If both the warning lamp and the

shutdown lamp come on during

engine operation, this indicates one

of the following conditions.

The engine is either shutdown or an

engine shutdown is imminent. One or

more monitored engine parameters

have exceeded the limit for an engine

shutdown. This pattern of lamps can be

caused by the detection of a serious

active diagnostic code.

1. One or more of the shutdown

values for the engine protection

strategy has been exceeded.

2. A serious active diagnostic code

has been detected.

After a short period of time, the

engine will shut down.

This document is printed from SPI². Not for RESALE

![]()

20

KENR9116-01

Troubleshooting Section

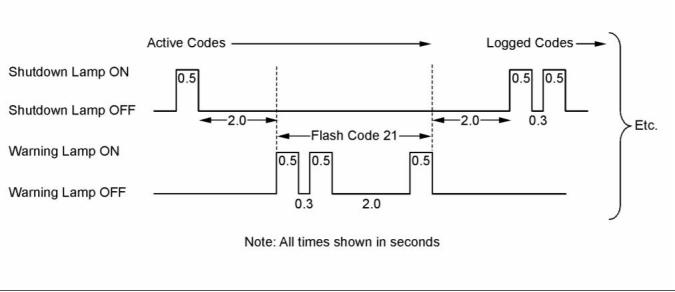

Flash Codes

The “Flash Code” feature is used to flash the code

of all active diagnostic codes and logged diagnostic

codes.

The sequence for the flash code is started by moving

the keyswitch to “Off” and then moving the keyswitch

to “On” twice within a period of three seconds. After

a delay of 2 seconds, the “Shutdown” lamp will flash

once for a period of half a second. This sequence

indicates the start of the active fault codes. After

a further delay of 2 seconds, the “Warning” lamp

will flash repeatedly in order to indicate the active

diagnostic codes. Each flash will be on for half a

second and off for 300 milliseconds. The “Warning”

lamp will remain off for 2 seconds between each digit

of a code. If there is more than one active diagnostic

code, the “Shutdown” lamp will go off for 2 seconds.

The lamp will then come on for a period of half a

second. The “Warning” lamp will go off for a period of

2 seconds before starting the next code. If there are

no active diagnostic codes, the “Warning” lamp will

flash the code “551”. Refer to Troubleshooting Guide,

“No Diagnostic Code Detected”.

As an example, an active diagnostic code of “21” is

indicated by the “Warning” lamp coming on for 500

ms, then off for 300 ms, then on for 500 ms, then off

for 2000 ms, then on for 500 ms and then off.

g01779334

Illustration 9

Timing of the flash codes

After all of the active diagnostic codes have been

displayed, the “Shutdown” lamp will go off for 2

seconds. The “Shutdown” lamp will flash twice in

order to indicate the start of the sequence that will

display the logged diagnostic codes. The process for

flashing logged diagnostic codes is identical to the

process for flashing active diagnostic codes.

Note: If there are no logged codes then the “551”

code should be flashed again.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9116-01

21

Troubleshooting Section

After all of the codes have been displayed, the

“Shutdown” lamp will flash 3 times in order to

indicate that there are no further codes. Cycling the

keyswitch twice within a period of 3 seconds will

start the process again. All codes will be displayed in

ascending numerical order.

Note: If an ECM is to be used as a test ECM, “Test

ECM Mode” must be selected on the electronic

service tool before the engine serial number is

entered.

Use the electronic service tool to read the parameters

in the suspect ECM. Record the parameters in

the suspect ECM. Install the flash file into the new

ECM. After the ECM is installed on the engine, the

parameters must be programmed into the new ECM.

Refer to the Troubleshooting Guide, “Diagnostic

Code Cross Reference” for the diagnostic code that

relates to the flash code.

Note: Flash codes are always sent in ascending

numerical order.

Note: When a new ECM is not available, an ECM

can be used from an engine that is not in service.

The ECM must have the same serial number

suffix. Ensure that the replacement ECM and the

part number for the flash file match the suspect

ECM. Be sure to record the parameters from the

replacement ECM. Use the “Copy Configuration ECM

Replacement” function in the electronic service tool.

i04319696

Replacing the ECM

NOTICE

If the flash file and engine application are not matched,

engine damage may result.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting, and repair of the product. Be prepared

to collect the fluid with suitable containers before

opening any compartment or disassembling any com-

ponent containing fluids.

Perform the following procedure in order to replace

the ECM.

1. Connect the electronic service tool to the

diagnostic connector.

Dispose of all fluids according to local regulations and

mandates.

2. Use the “Copy Configuration ECM Replacement”

function from the electronic service tool. If the

process is successful, proceed to Step 4. If the

“Copy Configuration” failed, proceed to Step 3.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: Record any Logged Faults and Events for your

records.

The engine is equipped with an Electronic Control

Module (ECM). The ECM contains no moving parts.

Follow the troubleshooting procedures in this manual

in order to be sure that replacing the ECM will correct

the fault. Verify that the suspect ECM is the cause

of the fault.

3. Record the following parameters:

•

•

•

Record all of the parameters on the

“Configuration” screen.

Record all of the parameters on the “Throttle

Configuration” screen.

Note: Ensure that the ECM is receiving power

and that the ECM is properly grounded before

replacement of the ECM is attempted. Refer to the

schematic diagram.

Record all of the parameters on the “Mode

Configuration” screen.

• Record the serial numbers of the electronic unit

injectors. The injector serial numbers are shown

on the “Injector Trim Calibration” screen.

A test ECM can be used in order to determine if the

ECM on the engine is faulty. Install a test ECM in

place of the suspect ECM. Install the flash file with

the correct part number into the test ECM. Program

the parameters for the test ECM. The parameters

must match the parameters in the suspect ECM.

Refer to the following test steps for details. If the

test ECM resolves the fault, reconnect the suspect

ECM. Verify that the fault returns. If the fault returns,

replace the ECM.

Note: If the parameters cannot be read, the

parameters must be obtained elsewhere. Some

parameters are stamped on the engine information

plate, but most parameters must be obtained from

the PTMI data on the Perkins web site.

4. Remove power from the ECM.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

22

KENR9116-01

Troubleshooting Section

5. Remove the ECM. Refer to Disassembly and

Assembly, “Electronic Control Module - Remove

and Install”.

Diagnostic Trouble Code – When a fault in the

electronic system is detected, the ECM generates a

diagnostic trouble code. The diagnostic trouble code

indicates the specific fault in the circuitry.

6. Install the replacement ECM. Refer to Disassembly

and Assembly, “Electronic Control Module -

Remove and Install”.

Diagnostic codes can have two different states:

• Active

7. If the replacement ECM is to be used as a test

ECM, select “Test ECM Mode” on the electronic

service tool.

• Logged

Active Code – An active diagnostic code indicates

that an active fault has been detected by the control

system. Active codes require immediate attention.

Always service active codes prior to servicing logged

codes.

8. Download the flash file.

a. Connect the electronic service tool to the

diagnostic connector.

b. Select “WinFlash” from the “Utilities” menu of

the electronic service tool.

Logged Code – Every generated code is stored

in the permanent memory of the ECM. The codes

are logged for 100 operating hours unless a code is

cleared by use of the electronic service tool.

c. Select the downloaded flash file.

9. If necessary, use the electronic service tool to clear

the rating interlock. To clear the rating interlock,

enter the factory password when the electronic

service tool is first connected. Activating the Test

ECM mode will also clear the rating interlock.

Logged codes may not indicate that a repair is

needed. The fault may have been temporary. The

fault may have been resolved since the logging

of the code. If the system is powered, an active

diagnostic trouble code may be generated whenever

a component is disconnected. When the component

is reconnected, the code is no longer active. Logged

codes may be useful to help troubleshoot intermittent

faults. Logged codes can also be used to review the

performance of the engine and the electronic system.

10. Use the electronic service tool to program the

parameters. Perform the following procedure.

a. If the “Copy Configuration” procedure was

successful, use the “Copy Configuration, ECM

Replacement” function to load the configuration

file into the ECM.

i04215569

Sensors and Electrical

Connectors

Note: During the following procedure, factory

passwords may be required.

b. If the “Copy Configuration” procedure failed,

configure the parameters individually. The

parameters should match the parameters from

step 3.

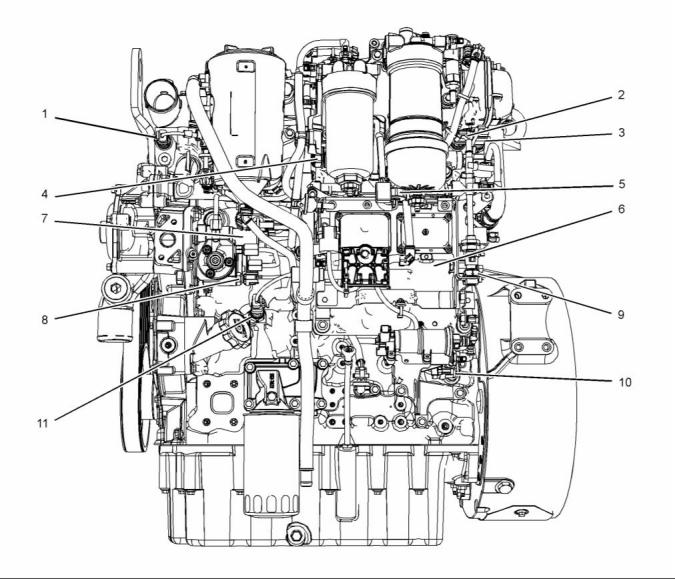

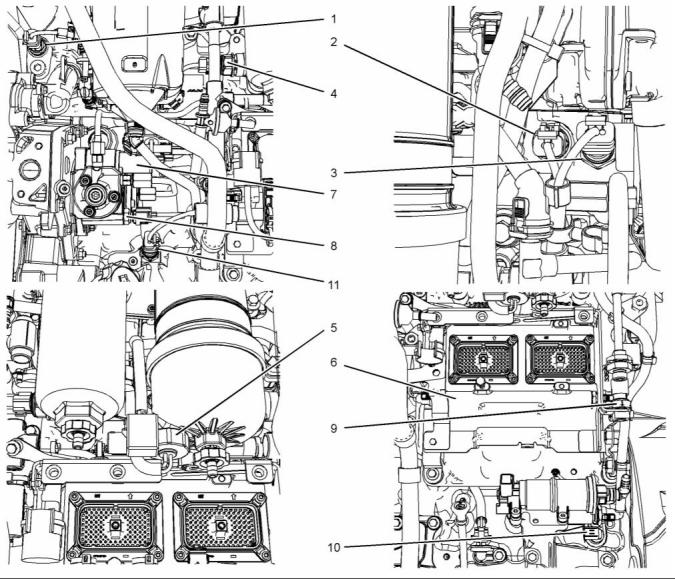

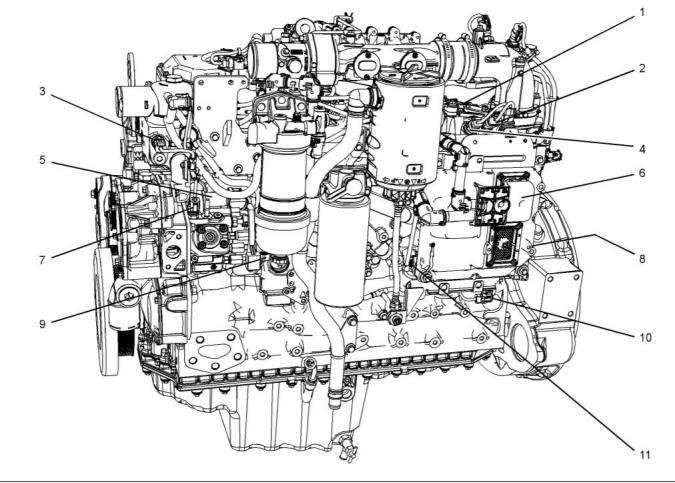

The Electronic Control Module (ECM) and most

of the engine sensors are located on the left side

of the engine. For the 1204E-E44 engine, refer to

Illustration 10. For the remaining sensors that are

attached to the 1204E-E44 engine, refer to Illustration

12. For the 1206E-E66 engine, refer to Illustration 14

. For the remaining sensors that are attached to the

1206E-E66 engine, refer to Illustration 16. For the

sensors and components on the Clean Emissions

Module (CEM), refer to Illustration 18.

Perform the “Fuel System Verification Test”.

11. Check for logged diagnostic codes. Factory

passwords are required to clear logged events.

i03951470

Self-Diagnostics

Note: In the following illustrations, some components

have been removed in order to improve visibility.

The Electronic Control Module (ECM) can detect

faults in the electronic system and with engine

operation. A self-diagnostic check is also performed

whenever power is applied to the ECM.

When a fault is detected, a diagnostic trouble code

is generated. This code conforms to the SAE J1939

standard. An alarm may also be generated.

This document is printed from SPI². Not for RESALE

![]()

KENR9116-01

23

Troubleshooting Section

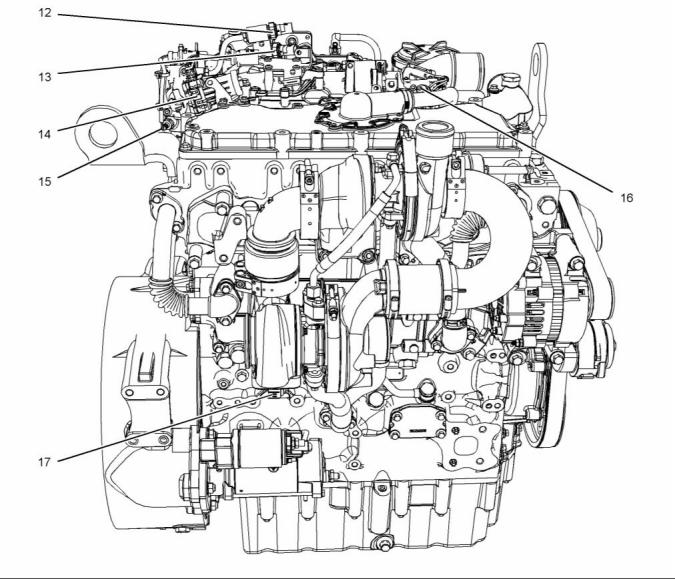

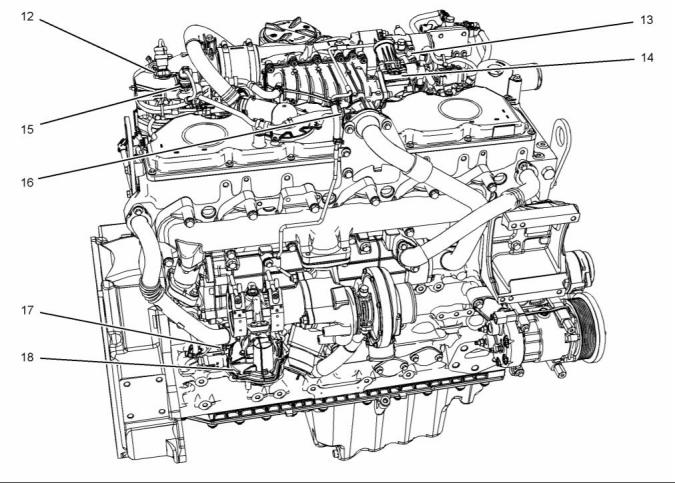

Typical 1204E-E44 Engine

g02479176

Illustration 10

Sensor locations on the left side of a typical 1204E-E44 engine

(1) Coolant temperature sensor

(2) Intake manifold air temperature sensor

(3) Intake manifold pressure sensor

(4) Fuel rail pressure sensor

(5) Water-in-fuel switch

(8) Fuel temperature sensor

(6) Electronic Control Module (ECM)

(7) Suction control valve for the

high-pressure fuel pump

(9) Barometric pressure sensor

(10) Primary speed/timing sensor

(11) Oil pressure sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

24

KENR9116-01

Troubleshooting Section

g02479258

Illustration 11

Close up views of sensor locations on the left side of a typical 1204E-E44 engine

(1) Coolant temperature sensor

(2) Intake manifold air temperature sensor

(3) Intake manifold pressure sensor

(4) Fuel rail pressure sensor

(5) Water-in-fuel switch

(8) Fuel temperature sensor

(6) Electronic Control Module (ECM)

(7) Suction control valve for the

high-pressure fuel pump

(9) Barometric pressure sensor

(10) Primary speed/timing sensor

(11) Oil pressure sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9116-01

25

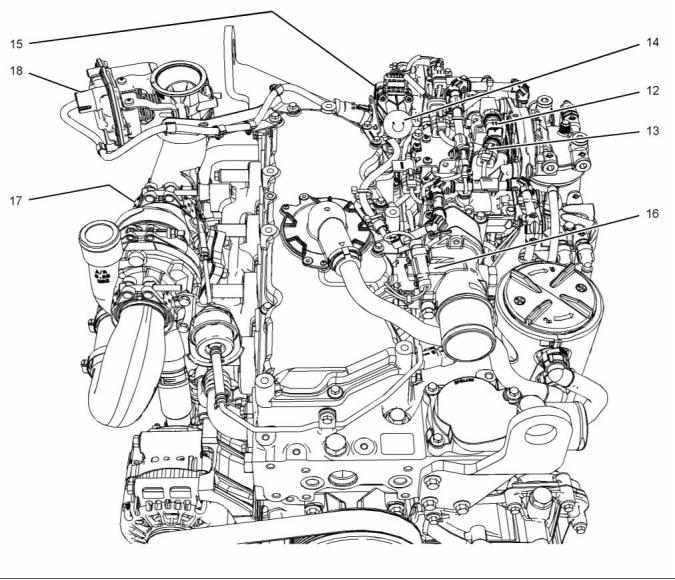

Troubleshooting Section

g02481176

Illustration 12

Sensor locations on the right side and the top of a typical 1204E-E44 engine

(12) NRS outlet pressure sensor

(13) NRS inlet pressure sensor

(14) NRS valve

(15) Nox Reduction System (NRS)

temperature sensor

(16) Wastegate regulator

(17) Secondary speed/timing sensor

(18) Exhaust back pressure valve (not

illustrated)

This document is printed from SPI². Not for RESALE

![]()

![]()

26

KENR9116-01

Troubleshooting Section

g02481197

Illustration 13

Close up views of sensor locations on the top of a typical 1204E-E44 engine

(12) NRS outlet pressure sensor

(13) NRS inlet pressure sensor

(14) NRS valve

(15) Nox Reduction System (NRS)

temperature sensor (not illustrated)

(16) Wastegate regulator

(17) Secondary speed/timing sensor (not

illustrated)

(18) Exhaust back pressure valve

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9116-01

27

Troubleshooting Section

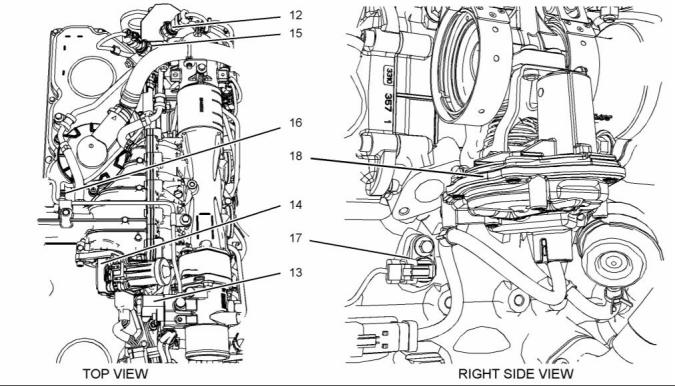

1206E-E66 Engine

g02481236

Illustration 14

Sensor locations on the left side of a typical 1206E-E66 engine

(1) Fuel rail pressure sensor

(5) Suction control valve for the

high-pressure fuel pump

(6) Electronic Control Module (ECM)

(7) Fuel temperature sensor

(8) Barometric pressure sensor (not shown)

(9) Water-in-fuel switch

(10) Primary speed/timing sensor

(11) Oil pressure sensor

(2) Intake manifold pressure sensor

(3) Coolant temperature sensor

(4) Intake manifold air temperature sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

28

KENR9116-01

Troubleshooting Section

g02481796

Illustration 15

Close up views of sensor locations on the left side of a typical 1206E-E66 engine

(1) Fuel rail pressure sensor

(5) Suction control valve for the

high-pressure fuel pump

(6) Electronic Control Module (ECM)

(7) Fuel temperature sensor

(8) Barometric pressure sensor

(9) Water-in-fuel switch

(10) Primary speed/timing sensor

(11) Oil pressure sensor

(2) Intake manifold pressure sensor

(3) Coolant temperature sensor

(4) Intake manifold air temperature sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9116-01

29

Troubleshooting Section

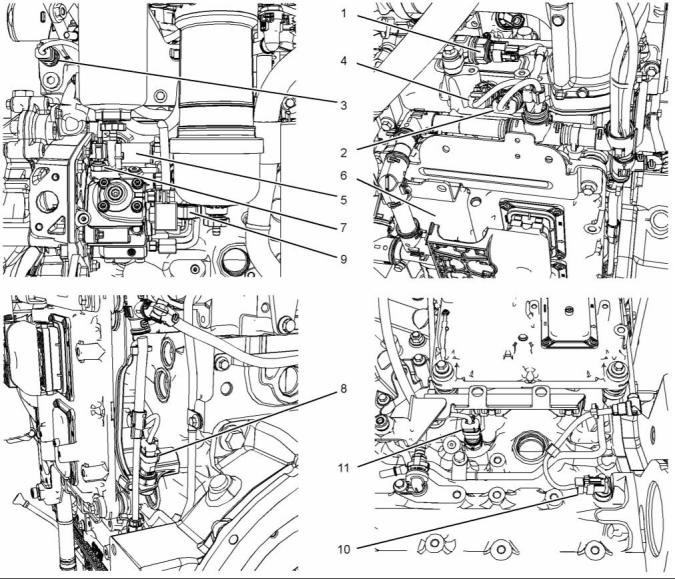

g02483578

Illustration 16

Sensor locations on the right side and the top of a typical 1206E-E66 engine

(12) NRS outlet pressure sensor

(13) Wastegate regulator

(14) NRS valve

(15) NRS inlet pressure sensor

(16) Inlet temperature sensor for the NOx

Reduction System (NRS)

(17) Secondary speed/timing sensor

(18) Exhaust back pressure valve

This document is printed from SPI². Not for RESALE

![]()

![]()

30

KENR9116-01

Troubleshooting Section

g02395457

Illustration 17

Close up views of sensor locations on the right side and the top of a typical 1206E-E66 engine

(12) NRS outlet pressure sensor

(13) Wastegate regulator

(14) NRS valve

(15) NRS inlet pressure sensor

(16) Inlet temperature sensor for the NOx

Reduction System (NRS)

(17) Secondary speed/timing sensor

(18) Exhaust back pressure valve

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9116-01

31

Troubleshooting Section

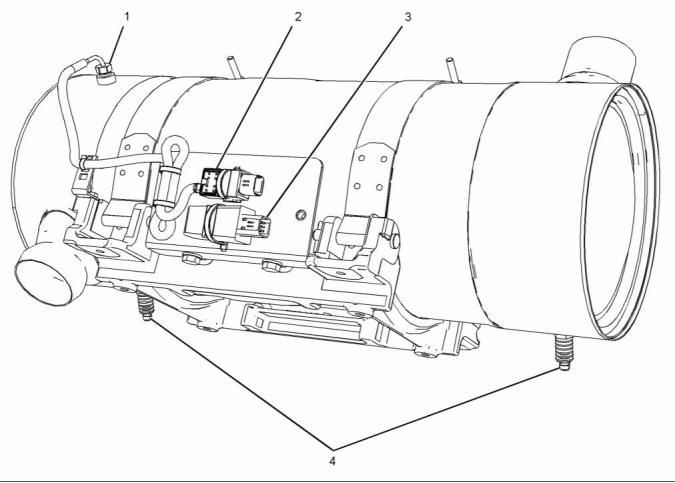

Clean Emissions Module (CEM)

g02095035

Illustration 18

Sensors and components on a typical CEM

(1) Temperature probe for the inlet to the

DPF

(2) Inlet temperature sensor

(3) Aftertreatment identification module

(4) Soot antennas

i04319697

Table 5

Engine Wiring Information

Color Codes for the Harness Wire

Color Code

Color

Color Code

Color

BK

BR

RD

OR

YL

Black

BU

PU

GY

WH

PK

Blue

Harness Wire Identification

Brown

Red

Purple

Gray

Perkins identifies all wires with 11 solid colors. The

circuit number is stamped on the wire at a 25 mm

(1 inch) spacing. Table 5 lists the wire colors and the

color codes.

Orange

Yellow

Green

White

Pink

GN

For example, a wire identification of F730-OR on

the schematic would signify an orange wire with the

circuit number F730. F730-OR identifies the power

supply for the oil pressure sensor.

Note: Always replace a harness wire with the same

gauge of wire and with the same color code.

This document is printed from SPI². Not for RESALE

![]()

![]()

32

KENR9116-01

Troubleshooting Section

Note: In the following diagrams, “Pxxx” signifies a

plug and “Jxxx” signifies a jack.

Schematic Diagrams

1204E-E44 Engine

g02101233

Illustration 19

Schematic diagram of the 1204E-E44 engine connections to the J2 connector on the ECM

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9116-01

33

Troubleshooting Section

1206E-E66 Engine

g02101353

Illustration 20

Schematic diagram of the 1206E-E66 engine connections to the J2 connector on the ECM

This document is printed from SPI². Not for RESALE

![]()

![]()

34

KENR9116-01

Troubleshooting Section

NOx Reduction System (NRS)

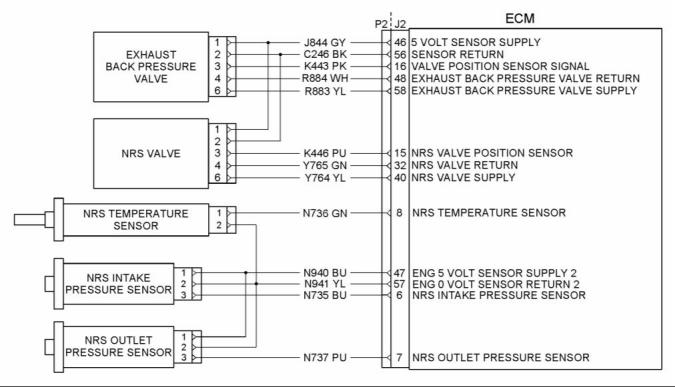

g02101473

Illustration 21

Schematic diagram of the NRS equipment for the 1204E-E44 and 1206E-E66 engines

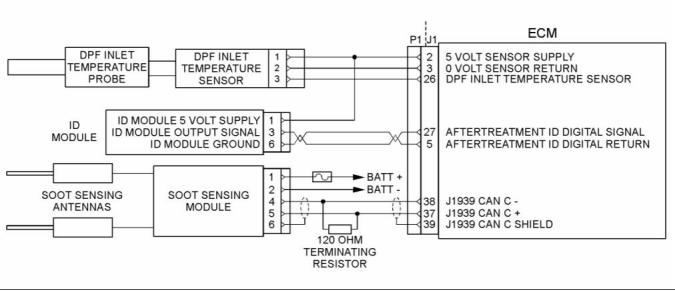

Clean Emissions Module (CEM)

g02554116

Illustration 22

Schematic diagram of the Clean Emissions Module (CEM)

Wiring for the Application

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR9116-01

35

Troubleshooting Section

g02488496

Illustration 23

Schematic Diagram for a Typical Application

This document is printed from SPI². Not for RESALE

![]()

![]()

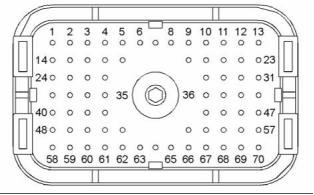

36

KENR9116-01